our operations

new technologies help improve worker safety

1 min read | august 19, 2024

Chevron is using several new technologies to help improve worker safety.

As a Chevron asset retirement manager, David Beckmann gets excited about new technologies that help improve efficiency in offshore operations. And he gets even more excited when they play a role in worker safety.

“Making sure workers go home safely to their families at the end of each shift is our top priority,” he said. “Nothing is more important.”

safety first

Preventing serious accidents and fatalities is one of Chevron’s top priorities. This is why Chevron is leaning into technology that helps do just that. Here are just a few examples:

diving down

Another new technology that’s helping Chevron improve safety was developed by Control Cutter. Chevron has deployed the Control Cutter pinning and cutting tool at several of its offshore locations. It pins underwater pipes in place before severing them during a platform’s dismantling.

Control Cutter developed technical solutions to reduce risks and improve efficiency in the decommissioning of offshore wells.

Control Cutter, a Norwegian startup, develops tools used primarily in offshore decommissioning to improve efficiency and safety.

With this tool’s fully automated systems, a person can remain at a safe distance and use a tablet to operate the machine. They can even operate it from across the world. All it takes is a reliable internet connection.

Gopal Kothari, a technology deployment and adoption manager, said the tool requires minimal human intervention. It reduces the need for workers to enter red zones—high-risk areas where equipment is performing cuts—by more than 90%.

Learn more about how Chevron prioritizes workforce safety.

topics covered

related content

-

chevron VP talks technology and energy transition

chevron VP talks technology and energy transitionour operationsnovember 14, 2024

-

marking a milestone in US gulf of mexico

marking a milestone in US gulf of mexicoour operationsnovember 06, 2024

-

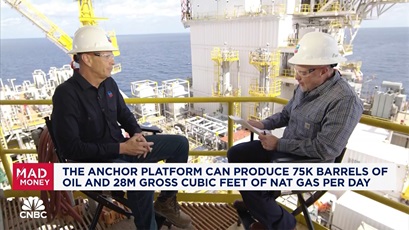

CNBC joins chevron CEO in US gulf of mexico to discuss deepwater achievements

CNBC joins chevron CEO in US gulf of mexico to discuss deepwater achievementsour operationsoctober 29, 2024

-

‘tomorrow’s world today’ features chevron’s technology and innovation

‘tomorrow’s world today’ features chevron’s technology and innovationour operationsoctober 15, 2024

chevron email updates

Subscribe to our newsletter to receive news and updates.